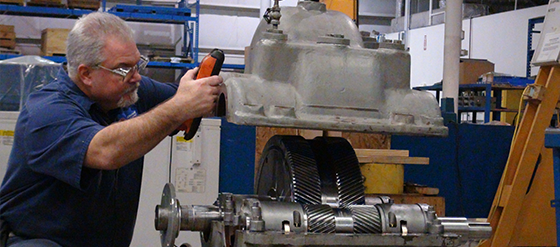

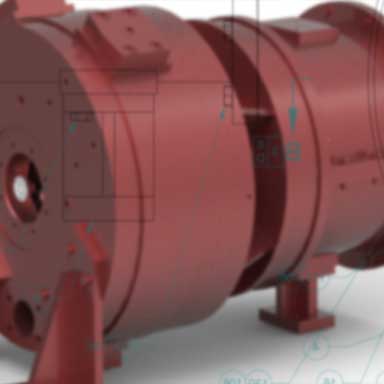

Testing and Inspection

Cincinnati Gearing Systems is capable of testing and/or inspecting a single gear or an entire gearbox. Our equipment, software and expertise assures customers they are receiving a quality product.

Services the make and model / Advantages

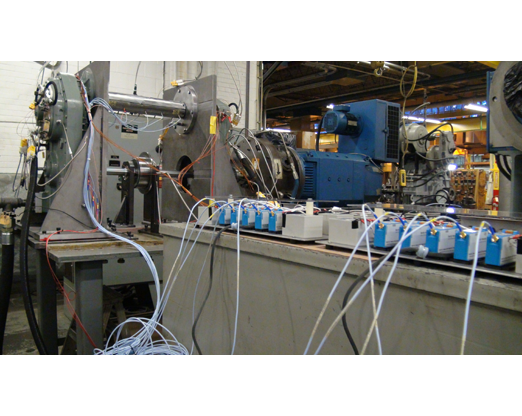

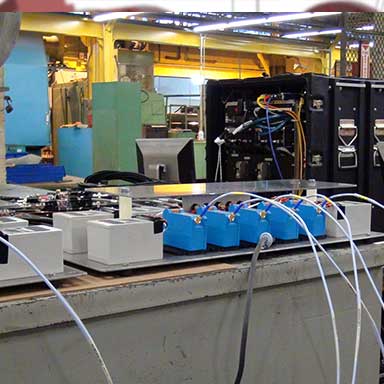

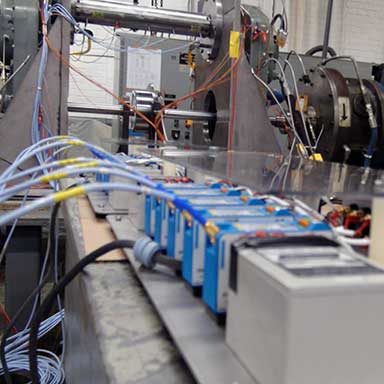

- Full-Speed Testing

- Full/Partial Load

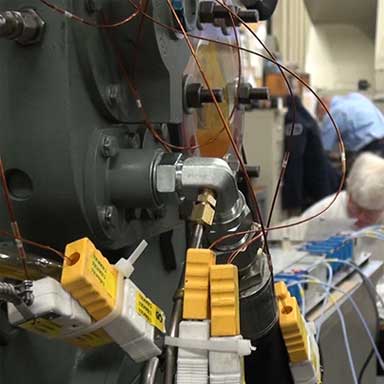

- Oil Flow & Temperature Monitoring

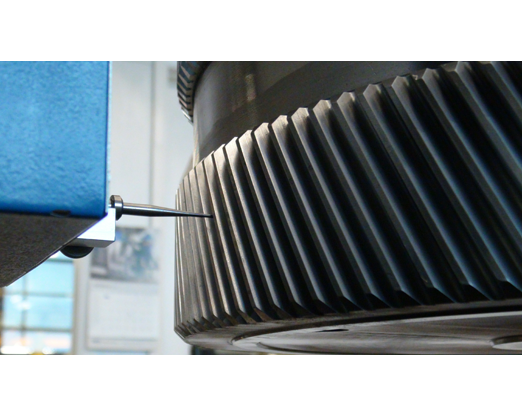

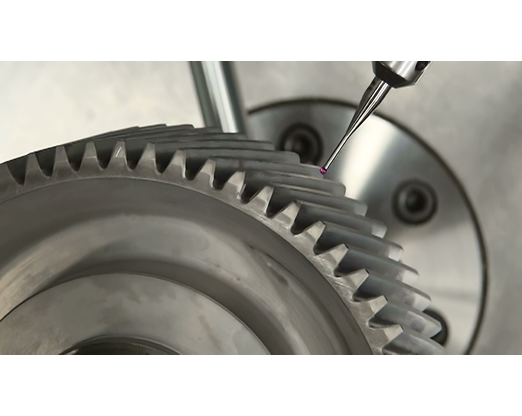

- Gear Tooth Inspection

- Noise and Vibration Analysis

- Non-Destructive Testing

- Magnetic Particle Inspection

- Nital Etch

- On-site Inspection and Repair Services

- Design and Failure Analysis

- Emergency Repairs

- Reverse Engineering

- Surface Finish Inspection

- Hardness Inspection

- Metallurgical Analysis

- Babbitted Bearing Repair/Replacement

- Redesigns and Upgrades to Enhance Performance and Durability

- In-House Gear Design

- In-House Reverse Engineering

- In-House Gear Manufacturing

- Housing Repairs - Sleeve, Rebore, etc.

- Detailed Repair Proposal Including Photographs and Full Statement of Work

- Offering Cost Effective Alternatives to New Equipment

| Machine | Capabilities |

|---|---|

| TPF 40 Gear Checker | Gear Chart .5" - 11.5' |

| Hofler Gear Checker | 63" and Internal |

| M&Mamp; Gear Checker | 2' |

| CMM | 4' x 8' |

| Mag. Particle Tester (2) | |

| Hardness Checker |

513 527 8600

513 527 8600  sales@cincinnatigear.com

sales@cincinnatigear.com